|

|

|

KRM

Trisem

The KRM

Trisem has been developed to provide a low cost high output

versatile drill. Extra close coupling saves weight and reduces

overhang allowing the use of a lighter tractor for reduced

compaction. The unobstructed large capacity hopper features

a full width lid for easy filling and unimpeded access, its

V shaped base ensured the hopper empties fully.

|

|

|

|

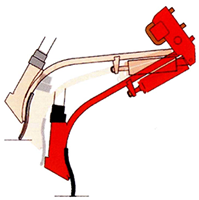

KRM

Elite Coulter

|

|

Elite

tine coulters are mounted in three rows on equal length arms.

Pressure is supplied by a heavy duty spring positioned at

a shallow angle below the tine. This geometry ensures that

for each movement of the tip the corresponding deflection

of the spring is small resulting in more even pressure and

therefore depth. This system works equally well when shallow

drilling (rape) or deep drilling (peas) as well as in varying

soil conditions.

|

|

|

|

| |

|

|

Standard

Features

|

|

|

|

The

solatronic control box monitors all key areas of sowing including;

forward speed, area sown, fan speed and tramline management. A hopper

level indicator is visible from the tractor seat. |

|

| When

on a tramline bout the tramline clutches disengages drive to four

coulters (two for each wheeling). This prevents over sowing and ensures

a clean start to each tramline. |

|

|

|

The

tramlining sequence is advanced automatically when the operator moves

the markers. The angle of the large diameter marker disc's can be

adjusted to ensure a clear mark is left in difficult seed beds. The

markers fold vertically to allow close sowing to hedges. |

|

|

Seed

is metered from the hopper through individual fluted rollers. These

3 position rollers can handle rape, cereals and peas/beans without

special parts or complex adjustments. Application rates are set by

the variator and be adjusted from 2kg/ha to 400kg/ha. This stepless

system ensures the exact target rate can be achieved. A spring loaded

seed flap protects the feed rollers from damage by foreign objects

and ensures even metering. Its angled leading edge gives progressive

metering so an even row spacing |

|

|

|

Three

rows of elite tine coulters with a large stagger and 13.6cm row spacing

ensure even seed depth is maintained. Adjustment through a parallel

linkage ensures pressure on all coulters is identical for constant

depth. |

|

Two

rows of staggered following harrow tines leave a level seedbed.

Parallel mounting ensures each row is set at the same angle and

height. The harrow also incorporates a full width platform to aid

calibration and hopper filling.

|

|

| |

|

|

|

Optional

Cultivator

|

|

|

An optional

front cultivator is available, allowing two operations to be performed

in one pass. The cultivator has a row of ripper tines followed by

a row of arrow head tines to provide initial loosening and mixing.

As well as removing the tractors wheelings this system provides

leveling ready for the three rows of drill coulters. With this system

the cultivator can be removed when not required.

|

|

|

|

|

|